From product design and testing, to installation and servicing, it’s all in the detail

Breather holes and flimsy rubber waterproof plugs on the back face of a display unit are typical examples of a potential vulnerability in the harsh marine environment. Units that are sealed and have no means of being separated are often just not made to allow servicing nowadays. Details like these are at the heart of A+T Instruments’ mission – to up the instrument game and create the best systems on the market.

With a combined total of more than 60 years in the business, and having worked with some of the

biggest brands on the market, there is little that company founders Hugh Agnew and Richard Tinley and the team of experts at A+T don’t know about how instruments should work and almost more importantly, how instruments fail. As a result, all A+T instrument displays are CNC machined from PA66; a high-spec nylon material which is not only robust and fully sealed to withstand 0.5bar over or under pressure, but ensures that there is no corrosion when mounted in carbon or aluminium.

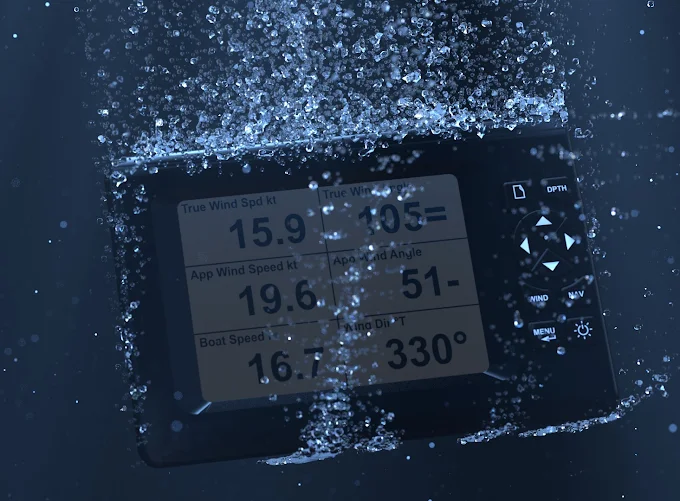

“All of our instruments are designed to withstand being fully immersed,” explains Tinley. “Every unit we ship is tested 1m underwater for 24 hours, before then being placed in an oven at 75 degrees Celsius. Our competitors simply can’t do this as their displays have breather holes or other openings.”

The robust method of construction using a series of machine screws to attach the front and back plates means that the waterproof units are serviceable, unlike many other instruments on the market, while software upgrades are performed via Bluetooth, ensuring that no plugs are required in the unit.

“All of our instruments are designed to withstand being fully immersed. Every unit we ship is tested 1m underwater for 24 hours, before then being placed in an oven at 75 degrees Celsius.”

“Our starting point was to make a range of displays to replace existing B&G systems that are fitted to most large yachts and are no longer supported or provided with spares.” says Agnew.

The idea quickly gained a strong following, especially in the superyacht market where replacing a complete instrumentation system would involve a major refit with a five- or six-figure price tag to match. Instead, replacing damaged or dysfunctional units with modern A+T equivalents that slip straight into existing cut-outs and connect with existing wiring looms has proved very popular with both superyachts and grand prix racers.

But that was just the start. From here came the development of the ATP processor. This too fits with the philosophy of allowing yachts to upgrade their electronics stepwise without changing wiring or throwing away existing working components.

“We currently have equipment aboard approximately 800 superyachts and the list is growing every month,” says Agnew. “An example of some of our most recent work is aboard Ningaloo,

a 45m Vitters/Dubois sloop.”

“We currently have equipment aboard approximately 800 superyachts and the list is growing every month.”

A+T’s business model is also different, in that it encourages customers to upgrade their electronics

stepwise rather than being geared towards wholesale replacement.

“They started with an A+T loadcell amplifier to replace an original that had got damaged by water in the forepeak. Subsequently, some original displays were replaced with new A+T Multi-Function Displays, until a full ATP processor upgrade was undertaken during a short refit. The actual installation was just a few days’ work, as the wiring and sensors remained unchanged.”

A+T’s work is varied, from new equipment for a Farr 40 and a Corel 45, to a system upgrade for a J Class that will use some original wiring and displays while new parts of the system will be run on A+T’s Ethernet-based instrument bus.

But there’s another side to the business that is proving popular, servicing. “We offer 24/7 phone and

email cover and are happy to help sort an issue with the legacy instruments on a boat even if it has

nothing from us,” continues Agnew.

“Instrumentation is our key business, but we know that service is what counts and we’re happy to be able to provide that too.”