The team of experts at A+T Instruments breakdown the types, technologies and troubleshooting of the most widely used sensors on race boats and superyachts, to help you find the best fit for your boat.

Wind Sensor Types: A Walk-Through

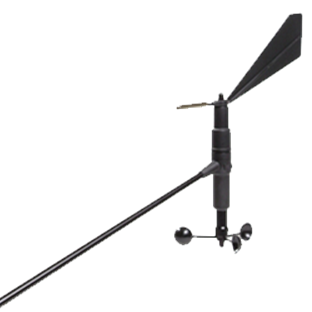

B&G 213

This sensor has been the workhorse for many thousands of boats since its introduction in the 1980s. The output is analogue, so pulse for speed and three voltage phases for determining angle. It interfaces into most B&G processors and all A+T processors. The mast cable contains 6 cores and screen.

B&G 300/700

B&G introduced this in about 2018 as a replacement for the 213. However, it uses a different mast bracket and mast cable. It transmits wind data in NMEA0183HS format at 10Hz. However, the data sent is heavily damped at several seconds. Only B&G processors later than H2000 and H3000 can use this sensor as well as A+T processors. There are some reports of units breaking from shock loading and the internal PCB being vulnerable to static/lighting proximity.

A+T 500 Series

Launched in 2022, the A+T 500 Series have a faster response, is better calibrated and tougher than either of the B&G units. In addition, all the parts of this are interchangeable with both B&G units, providing spare parts.

The A+T sensor can be supplied with an analogue output like the 213 which is preferred by many navigators as being ‘pure’ signal. Alternatively, it can be supplied with a digital output; the only difference is the internal PCB. The digital output is NMEA0183HS at 20Hz with undamped data for optimal use in mast motion compensation calculation.

A digital PCB can be fitted into an existing B&G 213 sensor to turn it into a digital sensor.

A+T also offers a service to rebuild a vertical carbon wand with the new A+T sensor, so saving considerable money and effort over buying a new vertical wand.

The body of the A+T sensor is graphite loaded, tough and fully conducting for protection against static and lighting proximity. The A+T bearings are ceramic giving excellent performance and lifetime.

Performance

| Unit | Angle Nominal Accuracy | Vane Response Time | Damping | Output | Output Rate | Conductive Housing |

| B&G 213 | 2 | >2 sec | None | Analogue | N/A | Yes |

| B&G 300/700 | 1 | >2 sec | ~3 sec | Digital | 10 Hz | No |

| A+T 500 | 0.2 | <1 sec | None | Analogue | N/A | Yes |

| A+T 510 | 0.2 | <1 sec | None | Digital | 20 Hz | Yes |

Troubleshooting

Wind sensors are one of the more vulnerable elements of an instrument system as the sensor is subject to shock loading, is very exposed to the elements and is mounted in the worst possible place for static or lightning damage. In addition, masts are removed and remounted, meaning the mast cable connections are disturbed.

To see if the wind sensor is working or not, look only at the displayed Apparent Wind Angle (AWA) and Apparent Wind Speed (AWS). If these tie up with the Windex and flags then fine, if not, then there is a wind sensor problem. Other wind issues can arise from calibration, heading or speed.

If the problem lies in the wind sensing, then it can only be one of three possibilities, and it is important first to find out which:

A. Masthead wind sensor (usually the internal pcb) if the mechanical parts are working

B. Cabling between masthead (including connectors) and the instrument processor

C. Processor failure.

A+T supply a range of test cables, so the wind sensor can be connected directly to the processor at deck level for testing and a masthead test connector which allows the mast cable and connector to be tested from the boat end (either mast junction box or processor). Watch our videos below to help.

Lightning

Lightning, or even associated static, is a real killer of wind sensors which are often the most exposed part of a yacht. They are also connected through the instruments 0V wire directly to the speed and depth sensors, which are just a few mm of epoxy from the seawater under the yacht, and so an easy path for discharge.

Worse than damaging just the wind sensor, is the damage that gets done to the whole instrument system and many components connected to this. Worse still is that often failures due to this do not come to light for many months after the initial damage. We will be publishing a separate article on instruments and lightning soon.

Maintenance & Spares

The key to troubleshooting is to have a set of well protected spare parts on-board. Minimum recommended spares for a smaller boat (<50’) would be:

- 1 x Masthead PCB

- 1 x set of 2 (upper and lower) bearings

- 1 x Wind Vane

- 2 x Wind Sensor Speed Cups

- Test cable and mast cable tester as above

- Larger boats or race boats will also normally carry a complete spare wind wand

Wind sensor should be dismounted annually, checked for mechanical damage and reconnected with a smear of silicone, or in the case of a B&G 213 or A+T H500 horizontal sensor, anti-seize grease on the thread (do not get onto the electronic connectors).

A+T bearings should be washed out with fresh water and then blown out with a blast of air. B&G bearings are not serviceable and certainly should not have any WD40 or oil applied.

Sensors can be sent to A+T for a full check and any replacement parts.

Questions & Answers

Q. Why have acoustic sensors not been included?

A. Acoustic sensors have the advantage of no moving parts. However they have two major disadvantages:

- Angular resolution. As the Apparent Wind Angle (AWA) is computed from two orthogonal wind speed measurements, the AWA of acoustic sensors is a lot less than wind vane. Even the highest specification research grade system offer 1°resolution and +/- 1° accuracy, while the A+T wind vane offers 10 x times this level. Upwind +/- 1° converts to potentially +/- 3° of True Wind Angle (TWA) and hence True Wind Direction (TWD)

- Affected by heel. The designs of these are generally a ‘mushroom’ enclosing the acoustic sensors which will affect the flow as the sensor is tilted.

Q. If I have a broken B&G 213 wind sensor can I replace it with a B&G 310 wind sensor ?

A. No, this requires a new mast bracket, a new mast cable and if you have older (B&G H2000 or H3000) then the whole instrument system including wiring would need to be replaced either with a new B&G system or any A+T processor.

Q. If I have a broken B&G 213 wind sensor can I replace it with an A+T unit.

A. Yes, A+T make a direct replacement, exactly plug in and go.

Q. Can you use an A+T Digital PCB in a B&G 213 wand to convert it to digital ?

A. Yes, and you can use the existing mast cable. The cable connections for the mast cable are available here.

Q. Can you put an A+T Digital PCB in a B&G 300 or 700 sensor to get rid of the damping and improve accuracy ?

A. Yes, the A+T PCB fits in these and provides the same data, just at a faster rate (20Hz).

Q. Can you put an A+T faster response wind vane on a B&G wind sensor ?

A. Yes, and this will improve the angular response. If putting an A+T vane onto a newer B&G 310 or 700 (vertical) sensor, then a new A+T top bearing must be used as well.

Q. Can the A+T ceramic bearings be used with B&G wind sensors ?

A. Yes, they are interchangeable on a B&G 213 sensor. If you want to use an A+T top bearing then you must use the A+T vane as well.

Note that A+T Instruments has no connection or affiliation with Navico/B&G.